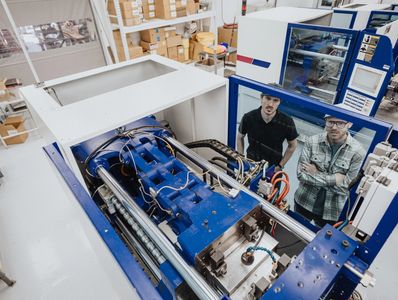

Engineering and Factory Automation

Factory automation is redefining competitiveness across industries. By integrating intelligent robotics, sensors, and AI-driven control systems, manufacturers can achieve unprecedented levels of precision, consistency, and efficiency.

Automation doesn’t just lower labor costs—it enhances throughput, reduces defects, and allows for real-time adaptation to demand and supply fluctuations. For executives, the strategic advantage lies in transforming fixed processes into dynamic, data-driven operations that improve profitability, resilience, and scalability while freeing human capital to focus on innovation and higher-value decision-making.

how we can help

Process Control Solutions

From controls design and BOM development to firmware, KrCM engineers assist in developing and implementing control solutions for our client's processes.

NRTL Compliant Controls

For factory panel installations requiring NRTL safety approvals from low voltage (under 1000 V) to intrinsically safe compliance, KrCM engineers provide design, compliant BOMs, and assembly using our approved panel shop partners.

Manufacturing Automation

Manufacturing Automation

We help our clients transform their manufacturing operations from a fixed process into an intelligent, adaptive system that drives profitability, innovation, and long-term strategic advantage. By integrating robotics, advanced control systems, data systems, and AI-driven analytics, we enable our client's scalability, supply chain stability, and faster response to market changes.

Business Consulting Services for KRC Morgan

The Intelligent Factory

Factories are moving toward a new definition of performance—measured not just in output per hour, but in adaptability, predictive accuracy, and system learning. The engineers who can integrate these capabilities into everyday operations will shape the future of the industry.

Copyright © 2025 KRC Morgan - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.